Finest Lift Maintenance Company Options Near Me for Specialist Lift Repairs

Finest Lift Maintenance Company Options Near Me for Specialist Lift Repairs

Blog Article

Necessary Elements to Consider for Elevator Upkeep

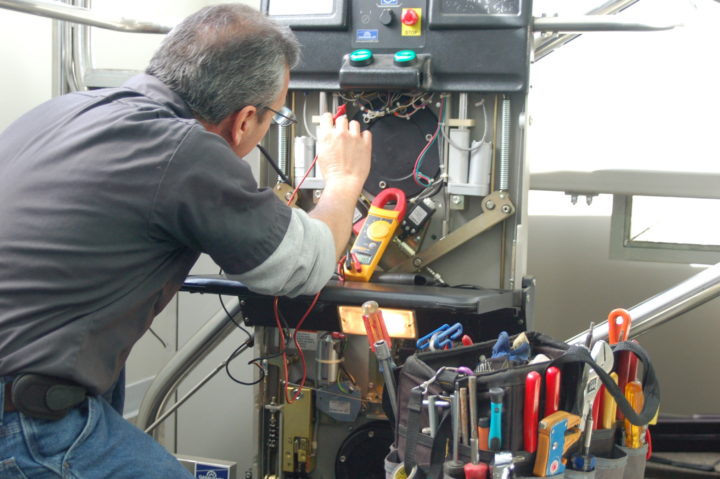

When it comes to the effective and secure operation of elevators, considering necessary maintenance factors is vital. It is necessary for constructing managers and maintenance employees to remain in advance of these elements to support the lift's efficiency criteria and conformity needs.

Regular Examination Schedules

Performing regular assessments not only enhances the total efficiency of the elevator yet likewise plays an essential function in following safety policies and sector standards. It makes sure that the lift operates efficiently, minimizing the danger of unforeseen break downs that might hassle passengers or compromise safety. Additionally, regular assessments add to lengthening the lifespan of the elevator equipment, eventually lowering maintenance prices and downtime.

To enhance the examination process, many building owners partner with qualified lift upkeep firms that concentrate on conducting thorough assessments and giving prompt upkeep services. By focusing on regular assessment schedules, stakeholders can support the safety and security, dependability, and performance of their lift systems.

Correct Lubrication Methods

Effective lubrication methods are crucial for keeping the optimum efficiency and durability of lift components. Correct lubrication techniques play a crucial role in protecting against wear and tear on moving parts, minimizing friction, and making sure smooth operation of the elevator system. When it pertains to elevator maintenance, utilizing the ideal lubricating substances in the correct quantities at the recommended intervals is key to reducing and preventing pricey fixings downtime.

To guarantee correct lubrication, elevator professionals need to adhere to producer standards relating to the kind of lubricating substance to be utilized for details elements such as bearings, gears, and guide rails - lift repair companies near me. Over-lubrication can draw in dust and particles, resulting in element malfunctions, while under-lubrication can trigger increased rubbing and early wear. Regularly set up lubrication upkeep should be consisted of in the general elevator maintenance strategy to maintain the system running successfully and safely

Monitoring Tear and put on

Lift upkeep personnel should conduct regular assessments to identify signs of wear on key parts such as ropes, sheaves, click to investigate guide rails, and bearings. In addition, keeping detailed upkeep records can aid in tracking the wear patterns of lift elements over time, allowing for anticipating maintenance preparation. By closely keeping an eye on wear and tear, upkeep groups can resolve problems proactively prior to they next escalate into costly repair services or unforeseen downtime, making certain the risk-free and efficient procedure of the elevator system.

Safety And Security Compliance Checks

Performing extensive safety and security conformity checks is crucial in guaranteeing the lift system meets all operational requirements and regulative standards. These checks also include validating that the lift's ability limitations, speed, and emergency communication systems are in line with safety and security requirements. Furthermore, adherence to security compliance checks can prevent mishaps, decrease liability risks for building proprietors, and expand the life expectancy of the elevator system.

Emergency Situation Action Planning

Because of the important significance of safety and security compliance checks in maintaining lift systems, a robust emergency situation feedback preparation strategy is vital to promptly and successfully address unexpected incidents. lift engineer course. Emergency response planning for elevators involves aggressive measures to make certain the safety and security of guests and maintenance personnel in case of emergency situations such as power outages, entrapments, or mechanical failings

Key parts of a reliable emergency action plan consist of developing clear interaction protocols, providing regular training to team on emergency treatments, maintaining current emergency get in touch with lists, and performing routine drills to practice action actions. Furthermore, it is vital to have designated employees in charge of working with emergency actions and guaranteeing that needed tools, such as emergency illumination and communication look at these guys devices, remain in functioning order.

Final Thought

Finally, it is vital to focus on normal inspection routines, appropriate lubrication techniques, keeping an eye on damage, safety compliance checks, and emergency response preparation for elevator upkeep. By applying these necessary aspects, building owners can guarantee the safety and efficiency of their lifts, eventually reducing the danger of crashes and malfunctions. Consistent maintenance techniques are important for lengthening the life-span of elevators and ensuring the health of people who rely on them for transportation.

Routinely scheduled lubrication upkeep ought to be consisted of in the total elevator upkeep plan to maintain the system running successfully and securely.

Elevator upkeep employees must conduct regular evaluations to recognize signs of wear on essential parts such as ropes, sheaves, guide rails, and bearings. In addition, maintaining comprehensive upkeep documents can assist in tracking the wear patterns of elevator parts over time, permitting for predictive upkeep preparation. By closely keeping an eye on wear and tear, maintenance groups can deal with problems proactively prior to they rise right into costly repairs or unexpected downtime, guaranteeing the secure and effective procedure of the lift system.

Report this page